CRI and Light Binning

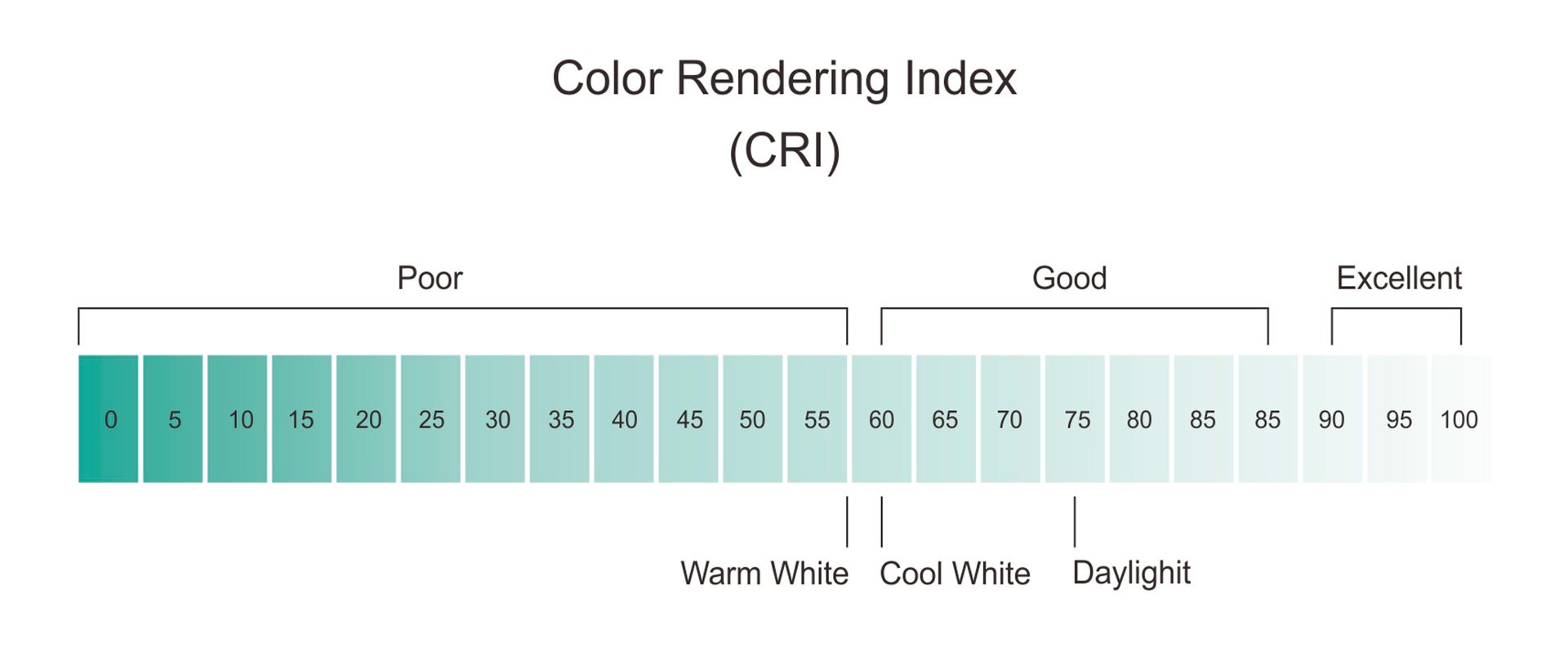

The Colour Rendering Index (CRI) is an index that varies from 0 to 100 and identifies the ability of a light source to render the colours of an illuminated object faithfully. The closer to 100, the better – or more accurate – colours should look under its light. The higher this value, the more the LED strip will respect the natural colour of the objects.

The parameter referred to by the CRI is the sunlight present during the day in different environments, which illuminates objects and surfaces. The Color Rendering Index identifies how much a lighting device faithfully reproduces the colour of objects as they are when illuminated by natural sunlight.

The CRI values of lighting fixtures are:

Cri> 90 or more:

Very high yield.The best option available often used in clothing stores, museums, showcases and supermarkets. Also referred to as class 1A.

Cri> 80: High yield.

Often used for schools, offices, commercial premises, public and private lighting. Also referred to as class 1B.

Cri> 60: Second Class.

Suitable for corridors, elevators, stairways and service areas, all those places where the quality of lighting does not play an important role.

CRI> 40: Third Class.

Suitable for industrial environments, warehouses, warehouses and logistics centres.

CRI> 20: Fourth and last Class.

Suitable for construction sites or unloading areas.

A CRI higher than 90 will guarantee us a color rendering of the objects as realistic as possible, the indication of 3 Step MacAdam ensures the absence of color variations visible to our eye.

Have you ever wondered why perhaps under an older street light, that your car doesn't look the same colour as it does in broad daylight? If so, this is because the CRI is low, so the appearance of colour is altered. This is fine for a street lamp, but retail outlets and designers certainly don't want to see colour alteration, so selecting the right level CRI is hugely important and consistency of this is vital.

Taking this a step further, we need to recognise that deviations occur frequently in the industrial production of LEDs and even LEDs from the same product batch differ in their properties. Binning is way of sorting the chips so that all the LEDs from one particular bin look the same and have similar light and colour output. Of course, binning can have serious implications on cost and lead time for manufacturers, but it is an invaluable process to specifiers and end-use customers and ensures that you will achieve quality and consistency. Binning systems effectively guarantee lighting standards, ensuring that the same LEDs deliver the same performance – and that you won’t be left disappointed when reordering LED's and can be confident that they will match.